Tokyo, 25 December, /AJMEDIA/

Tokai University and Fujitsu said they have developed a new technology to inspect the freshness of frozen tuna in Japan. Joint research focused on the development of novel ultrasound AI technology, resulting in the world’s first technique to measure the meat quality of frozen tuna without the need to cut or damage the product.

Demand for tuna both in Japan and globally has increased significantly, with 15 countries fishing and producing more than 50,000 tons of tuna in 2020. The recent global Japanese food boom has raised demand for high-quality tuna that is mostly used for sashimi (raw fish).

Most wild-caught, natural tuna is rapidly frozen on board commercial fishing boats, and subsequently delivered via distributers to restaurants and supermarkets to consumers. However, the quality of the tuna largely depends on the conditions at the time of fishing and the way it is handled throughout the distribution process.

Conventional methods for inspection of the freshness and meat quality of frozen tuna usually require inspectors to cut off the tail of the fish to visually examine a cross section of the tuna tail. Cutting the tail of the tuna often damages and ultimately lowers the value of the fish, and the process relies heavily on a limited number of experts trained to accurately conduct quality inspection.

Ultrasound waves are applied in quality testing in a variety of fields as a non-destructive testing method. However, the use for frozen products such as tuna proved to be difficult due to the high attenuation of acoustic waves.

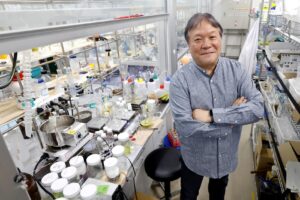

To address these issues, Tokai University under the lead of Professor Keiichi Goto, Department of Fisheries, School of Marine Science and Technology and Fujitsu conducted joint research examining frozen tuna with low-frequency ultrasound waves with low attenuation to inspect the freshness of the fish. By analyzing the waveforms using machine learning , the two parties successfully developed the world’s first method to determine the freshness of frozen tuna without the need to cut the product.

In order to find the optimum ultrasound frequency to examine frozen tuna, Tokai University and Fujitsu conducted trials at several wave frequencies. Tests showed that ultrasound waves with a relatively low frequency of about 500 kHz delivered optimum results.

To determine possible indicators of insufficient freshness , the two parties compared ultrasound waveforms from tuna specimens with good and insufficient freshness quality to examine whether waveforms differed depending on the freshness of the specimens. As a result, Tokai University and Fujitsu discovered that reflection intensity in the middle bone area of tuna specimen with insufficient freshness was especially intense. Based on these findings, the two parties created a machine learning model based on reflected waves from the middle bone of the tuna specimens that is able to correctly inspect the freshness of frozen tuna with an accuracy of 70% to 80%.

In addition to waveforms that can be easily differentiated by the human eye, the newly developed AI technology is also able to identify distinctions in waveforms that are difficult to visually perceive.

Possible use scenarios of the new technology

Wholesalers for marine products can easily inspect the freshness of a whole fish with a handheld device when buying tuna from fishermen.

Applied to inspections at facilities including fishing ports using belt conveyors, the technology could be used for automated batch inspections of the freshness of frozen tuna.

© JCN NEwswire